What is a Pipe Spool and How is it Used?

What Does Flame Retardant Mean? A Clear Explanation

21/09/2023Top 5 Paper Shredders for secure document disposal

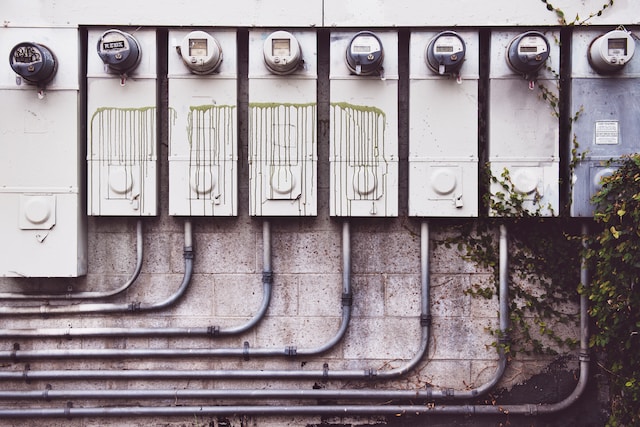

31/10/2024Pipe spools are an essential component in many industrial piping systems. They are manufactured by welding together sections of pipes and fittings to create a pre-fabricated unit that can be easily installed on-site. The spools are typically used for connecting different sections of a piping system, allowing for the efficient transfer of fluids or gases from one location to another.

One of the main advantages of using pipe spools is that they can significantly reduce the amount of time and labor required for on-site installation. Since the spools are pre-fabricated, they can be easily transported to the installation site and quickly connected to the existing piping system. This can help to minimize downtime and reduce the overall cost of the project.

Overall, custom pipe spools are a valuable tool for many industrial piping applications. They can help to streamline the installation process and improve the efficiency of fluid and gas transfer in a variety of settings. Whether you are working on a large-scale industrial project or a smaller commercial application, pipe spools are an important component to consider.

Fundamentals of Pipe Spools

Pipe spools are prefabricated sections of piping that are used in the construction of industrial piping systems. They are typically made up of multiple straight sections of pipe that are welded together, along with any necessary fittings, valves, and supports. The length of a pipe spool can vary depending on the specific requirements of the piping system, but they are typically between 6 and 12 feet in length.

Pipe spools are typically fabricated off-site in a dedicated facility, which allows for more efficient and cost-effective construction. This also ensures that the spools are built to the exact specifications of the piping system, which reduces the need for on-site modifications and repairs.

Read more: What Is The Process of Seamless Stainless Steel Pipes?

Primary Functions

The primary function of a pipe spool is to connect different sections of piping within a larger piping system. They are used to transport fluids and gases from one location to another, and can be found in a wide range of applications, including oil and gas, chemical processing, power generation, and more.

Pipe spools are also used to facilitate maintenance and repairs within a piping system. By using spools, individual sections of piping can be easily removed and replaced without having to shut down the entire system. This allows for more efficient maintenance and repair operations, which ultimately leads to less downtime and increased productivity.

Overall, pipe spools are an essential component of industrial piping systems, and their use can greatly improve the efficiency and reliability of these systems. By understanding the fundamentals of pipe spools, we can better appreciate their importance in modern industrial processes.

Applications and Industries

Oil and Gas Industry

In the oil and gas industry, pipe spools are extensively used for the transportation of liquids and gases. These spools are used to connect different sections of pipelines, such as from the wellhead to the processing plant, from the processing plant to the storage tanks, and from the storage tanks to the distribution network. The pipe spools used in this industry are typically made of materials that can withstand high pressures and temperatures.

Chemical Processing

In chemical processing plants, pipe spools are used to transport various chemicals and gases between different processing units. The spools are designed to handle corrosive and abrasive materials and are made of materials such as stainless steel, carbon steel, and exotic alloys. These spools are also used to connect different types of equipment, such as pumps, valves, and reactors.

Water Treatment Facilities

In water treatment facilities, pipe spools are used to transport water from one processing unit to another. These spools are designed to handle different types of water, such as potable water, wastewater, and industrial water. The spools used in this industry are typically made of materials that can withstand corrosion and erosion.

Construction and Infrastructure

Pipe spools are also used in construction and infrastructure projects such as buildings, bridges, and tunnels. These spools are used to transport water, gas, and other fluids between different parts of the structure. The spools used in this industry are typically made of materials that can withstand high pressures and temperatures.

In conclusion, pipe spools are used in a wide range of industries and applications. They are an essential component of pipelines and play a critical role in the transportation of fluids and gases.